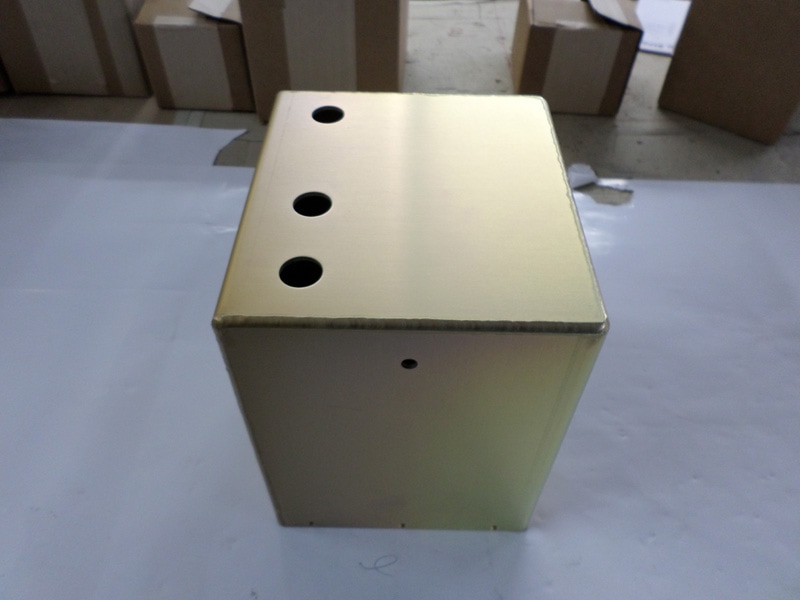

As an industry leading provider of premium quality anodizing services Automatic Anodizing can provide efficient processing of high volume components for a range of industries. The enclosure box shown here is constructed of 6061 aluminum, measures 12″ square, and is used by a customer in the telecommunications industry.

The aluminum parts were cleaned and etched prior to chromate conversion coating to provide a smooth, clean substrate. The chromate conversion coated parts were then masked and anodized using a sulfuric acid hard coat anodizing process. Chromate conversion coatings add corrosion resistance without affecting electrical conductivity, while anodizing provides an added layer of wear resistance to the aluminum surface. After anodizing, the enclosure was dyed and sealed, according to customer specifications. We can accommodate intricate parts that require selective masking as needed to provide a custom anodizing solution for virtually any application.

Finished parts were tested for coating thickness as well as abrasion and corrosion resistance, to ensure all specifications were met. We processed a total of 200 enclosure boxes with a turnaround time of two days for our customer in Rantoul, IL. For additional details regarding this custom surface finishing project, see the table below, or contact us directly.