Founded in 1947 during the exciting post-World War II expansion era, Automatic Anodizing is one of just a few ISO-certified companies worldwide offering expert chemical conversion coating and chromate conversion coating aluminum services. With nearly a century as a frontrunner in the business, our experience and commitment to providing exact fit-to-spec coatings make us your clear choice. Our flagship equipment allows us to provide sophisticated coating services with long-lasting protective finishes on all your aluminum parts.

Unmatched Durability, Quality, and Efficiency

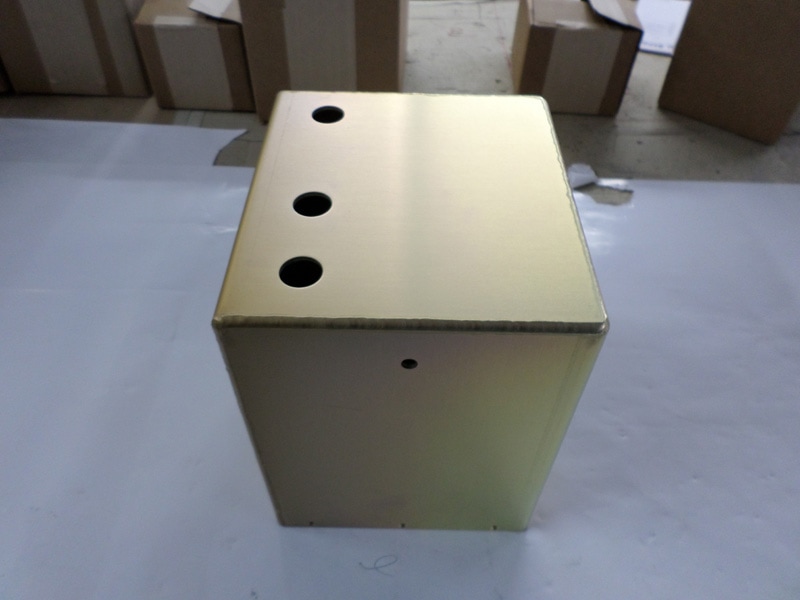

At Automatic Anodizing, we offer chemical and chromate conversion coatings that enhance the durability of your aluminum parts by increasing corrosion resistance and providing additional environmental protection against high temperatures or UV exposure.

This process helps to extend the life of your parts and save money on maintenance costs and overall performance. Moreover, our coatings fit perfectly into your production process and reduce downtimes as much as possible in your working schedule, so you can effortlessly fulfill orders on time at best without compromising on quality.

Tailored Industry Solutions

Our chemical conversion coating and chromate conversion coating aluminum services to precisely are tailor-made to match the demands of your industry’s specific needs:

- Aerospace: Provides superior protection for aircraft components, including airframes, landing gear, and turbine engine parts, ensuring they withstand extreme temperatures, high pressure, and corrosive environments encountered during flight.

- Military: Enhances the durability and operational performance of vital defense equipment, including components in armored vehicles, missile casings, and electronic enclosures to provide functioning even under abuse by saltwater (e.g. Navy), extreme heat/fire resistance, or combat friction wear.

- Medical: Offers biocompatible and antimicrobial coatings for medical devices, ensuring patient safety and compliance with stringent health regulations. Our coatings also provide durable, non-reactive surfaces for equipment that undergoes frequent sterilization, maintaining the integrity and functionality of surgical instruments and implantable devices.

- Food Services: Delivers clean, biocompatible food-processing equipment surfaces and nonreactive food-processing machine surfaces that will withstand regularization cleaning requirements while meeting strict regulatory standards.

- Automotive: Extends the lifecycle and reliability of engine parts, brake systems, or bodywork by protecting them from corrosion, wear & tear, and/or harsh environments. This helps to increase the life of critical automotive parts and their vehicles under any weather.

Why Choose Automatic Anodizing?

When you choose Automatic Anodizing for your chemical and chromate conversion coating needs, you’re partnering with a team dedicated to delivering premium solutions for your products’ success, ensuring customer satisfaction.

As an ISO 9001:2008-certified facility, we comply with the highest quality standards available. We also offer a complete selection of finishing services, including Type II anodizing services and Type III hard coat anodizing services, making us a one-stop shop for all your aluminum finishing needs.

Get Started with a Quote Today

Contact us today to learn how our superior coating solutions can help you deliver the highest quality products to your clients. Request a quote now and take the first step toward elevating your product’s performance and durability.